-

-

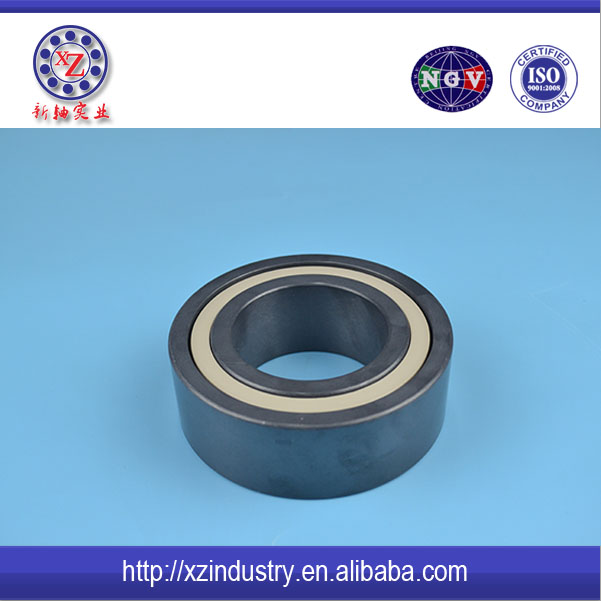

Product name: 4x12x4 mm si3n4 full ceramic ball bearing

-

-

Price: ASK

-

-

Post date: 2016-01-08

-

-

Stock Quantity:

-

Product Description:

Ceramic bearings are typically constructed with a ferrous inner and outer ring with ceramic balls in stead of steel.

They takes many advantages over steel bearings, such as higher speed and acceleration capability, increased stiffness, lower friction and more.

Ceramic bearings are made from Si3N4 which have greater hardness than steel.

Ceramic bearing balls have smoother surface than most steel bearings balls.

They require less lubricant and exhibit lubrication degradation, which results in increased bearing life.

Ceramic bearings are applied on high temperature, high speed, friction, semiconductor and food processing and so on.

|

|

|

|

|

|

|

Advantages of Ceramic Bearings |

u essentially increased life time u high stiffness because of high Young’s modulus,lower vibration u wear resistance and cost effective lubrication u electrical insulation and non-magnetism u high temperature resistance up to 1000oC u high corrosion resistance to most acids and alkalies |

|

Ceramic bearing material |

Si3N4 |

|

cage material |

PEEK/PTFE/PFA/graphite reinforcing PTFE |

|

Features: |

2)Precision: (P0),(P6),(P5),(P4) |

|

3)Bore Size: 3-110mm mm |

|

|

4)Outside Diameter:7-240 mm |

|

|

5)Noise level: Z1, Z2, Z3, Z4 |

|

|

6)Vibration Level: V1, V2, V3, V4 |

|

|

7)Clearance: C2, C3, C4, C5 |

|

|

8)hardness: 60-66 RC |

|

|

11)Cage: PEEK/PTFE/PFA/graphite reinforcing PTFE |

|

|

12) Limiting Speed: 60000 rpm(Grease);67000 rpm(Oil) |

|

|

ceramic bearing Application: |

Main shaft of machine tools, toys, roller skates, model navigation, motor-driven toys,medical equipment, cryogenic engineering, optics, high-speed machine tools, high-speed motor, printing machinery, food processing machinery. |

|

Brand name |

OEM |

|

Payment terms |

A: 30% T/T in advance .70% against copy of B/L |

|

Minimum Order Quantity:

|

1 piece |

|

Delivery Time:

|

In stock or lead time required |

|

Package |

Standard industrial package |

Features:

1) Out and inner ring: stainless steel or bearing steel

2) Ball: silicon nitride, zirconia or alumina

3) Retainer: PTFE, nylon, PEEK or stainless

4) Higher speed and acceleration, higher accuracy, reduced lubrication requirements, low thermal expansion, extended operating life-----------------------------------------------------------------

1) Materials:Si3N4,ZrO2,Al2O3

2) Usage: for bearings, inspection, and other rolling conditions

3) Exported to Japan, Korea, North America and Europe

4) Capacity: 3,000,000pcs/month for 5/32" silicon nitride balls 5) Diameter: 1/64" ~ 5/4" 6) Precision: G3 ~ G20Specifications:

1) 60% lighter than steel

2) Elastic modulus 50% larger than that of steel

3) Lower friction coefficient, rolls more freely

4) Coefficient of thermal expansion is only one third of that of steel

5) Superior surface finish

6) High temperature hardness is twice than that of steel

7) Never rust, and can roll without oil or grease

8) Better corrosion resistant than steel

Product Description:

Silicon nitride ceramic bearings:the rings and balls are all silicon nitride ceramics with cages made by PTFE, PEEK etc.

Full si3n4 full ceramic bearing1s rings and balls are made from Silicon Nitride full ceramic ,PTFE cage as standard structure.Also Nylon,Peek,PI,phonelic cage are available.

Full si3n4 ceramic bearing is more suitable for higher temperature and higher load application usage.Meantime,si3n4 ceramic is applied on high speed,high precision,highest precision abec7 can be achieved.

Our Services:

1. Full technical support from concept design to final product delivery

2. On-time delivery with no compromise on quality

3. High-quality product making with advanced equipment and techniques

4. Large-scale of proudction availabl

5. Lower cost (medium-size factory, 3000 square meters), but high-end quality only(the

same quality control system as per big factory)

6. Any questions to be sent will get response within 24 hours

FAQ

a) How to prolong service life of bearings?

Accurate installation and using,alignment,timely monitor,re lubrication etc.

b) Reason for bearings failure?